By lyuesword | 07 September 2020 | 1 Comments

History of Chinese Sword | Jian & Dao

Chinese Sword

Swords have a long history in China. Stone swords were used in prehistoric times. Bronze swords have been traced back to the bronze daggers of the Shang period. Bronze long swords suddenly appeared during the mid-third century BC. Later swords were made of iron or steel. These metals were wrought, never cast. Swords commonly reached a length of 70–100 cm, although longer swords have been found. Chinese iron swords were used in Japan from the third to sixth century AD, but were replaced with Korean and native Japanese swords by the middle of the Heian era [794-1185].

Chinese group all swords into two types, Jian (劍) and Dao (刀). Jian are dual edged and Dao are single edged.

History of Chinese Sword

Late Spring and Autumn to Early Warring States [500–350 BC] (春秋战国时期)

◾ Unlaminated bronze Jian are well developed at this time. Appearance of the earliest laminated bronze jian where

they utilize bronze with higher tin content for the cutting edges and bronze with lower tin content for the spine. It

results in a sword with harder cutting edges and a more flexible spine to absorb shock

◾ Extensive use of copper sulphides as anti-corrosion coatings on the bronze Jian

◾ Earliest iron and steel jian also appear, made by the earliest and most basic forging and folding techniques

◾ World's earliest book on alloys, The Artificers' Record, is written, with an explicit statement on the percentage

composition of the metals used in the Chinese bronze Jian

Middle and Late Warring States [350–221 BC] (战国后期)

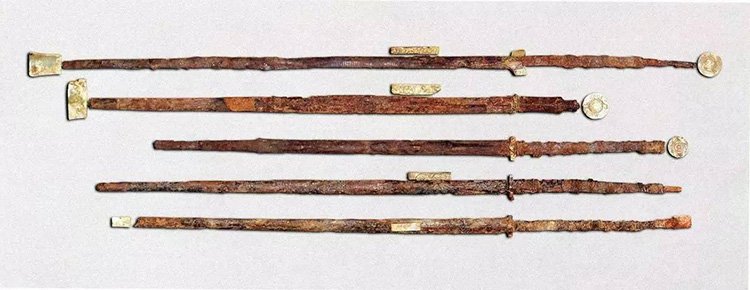

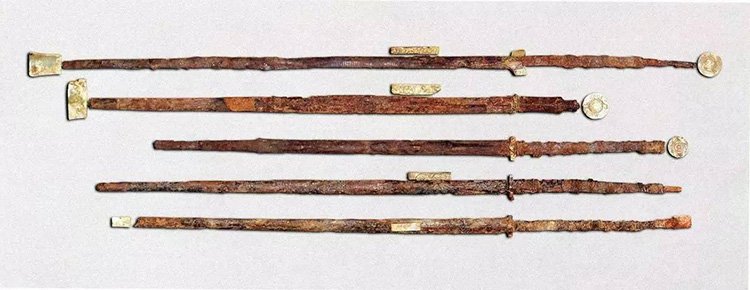

◾ Steel jian get longer to 1 meter or slightly more, with longer handles for two-handed use (though there are a few

Jian excavated that range from 1.2 to 1.4 meters)

◾ Bronze Jian also become longer to about 80 cm (earlier jian before have an average length of 60 cm and below)

Qin Dynasty [221–207 BC] (秦)

◾ Bronze Jian become even longer, reaching over 90 cm in length and the handle is extended to be long enough for

two-handed use

◾ Use of chromium oxide as an anti-corrosion protective coating on the bronze Jian. This process originates way

back from 700 BC. This invention was long lost for 2000 years before modern similar processes were developed

during our era in 1937 and the 1950s by Germans and Americans respectively

◾ The manufacture of steel jian that are 1 meter or longer is continued.

Early to Middle Han Dynasty [206 BC – 1 AD] (西汉)

◾ Longer steel Jian of length 1.2 meters or more are common

◾ Introduction of bronze Dao, followed by steel Dao. Steel Dao are as long as their steel double-edge counterparts

◾ Differential heat-treatment implemented on steel blades. This was to become a standardized process for the

construction of Chinese blades for the next 2000 years

◾ The prototype process of forging and folding sword blanks to improve the quality of the steel is further developed.

This particular process of forging and folding the sword blanks was to be perfected by the Middle Han (known as

the "refinings" process) to become a standardized process for later blades for almost 2000 years

◾ The introduction of ring pommels on bronze and steel Jian and Dao

◾ Earliest introduction of the tunkou (metal collar at the forte), made of bronze or copper

Middle to Late Han Dynasty [1–220 AD] (东汉/后汉)

◾ Bronze Jian and Dao, as well as steel jian are completely replaced by steel Dao

◾ Forge-welding/lamination (using higher carbon steel for the cutting edge and lower carbon steels for the core or

sandwich plates, depending on the design) introduced, a standardized process for later Chinese blades for almost

2000 years.

◾ Perfection of the forging and folding process resulting in blades being graded as thirty, fifty, and one hundred

"refinings". The higher the number, the better the blade's quality. This is the "refinings" process mentioned earlier.

It was also most likely transmitted to Korea.

◾ Earliest bronze and steel dao exported to Korea and Japan

◾ Use of white rayskin on the weapons' handle-grips introduced on Imperial Regulation blades

Early Three Kingdoms to Late Sui Dynasty [220–618] (三国早期至隋末)

◾ Continued use of the highly advanced "refinings" process

◾ Use of clay for differential heat-treatment introduced; when is unknown—it was invented sometime between 200

BC and 500 AD

◾ The development of the ridged cross-section (known later to the Japanese as kiriha-zukuri and shinogi-zukuri) in

the dao, probably sometime between 100 AD to 300 AD

◾ Introduction of the Sassanian/Persian style suspension mounts on Chinese Dao

◾ Probable introduction of Damascus wootz steel for use in Jian from India or the Middle East

Tang Dynasty [618–907] (唐)

◾ Swordmaking continues to progress in the Tang, maintaining the steady progress ever since the Han Dynasty

◾ Use of ring pommels discontinued in the Middle Tang

◾ Earliest use of disc-shaped guards to better protect the hand introduced in the Middle Tang

◾ Mass importation of quality Chinese blades to Japan in the Middle Tang

◾ Migration of Chinese and Korean swordsmiths to Japan where they transmitted their skills. Japanese smiths learn

from these smiths the processes of

◾ forge-welding/laminated construction

◾ ridged cross-sections (consisting of two variants known to the Japanese as kiriha-zukuri and shinogi-zukuri)

◾ differential heat-treatment using clay

◾ repeated forging and folding of sword blanks to enhance the quality of the steel ("refinings" process)

Song Dynasty [960–1279] (宋)

◾ Technical quality of Chinese weapons reaches a new high under Emperor Shenzong, a continuation from the Tang.

Multiple weapons quality assessment bureaus are set up. A manual on weapons manufacture and quality control,

Weapons' Laws and Methods is compiled and distributed to the relevant government bodies

◾ Under Emperor Shenzong, the horse-chopping backsword, or "zhanmadao", a heavy two-handed sword used by

anti-cavalry infantry is introduced in 1072 AD. (If Song dimensions are exactly the same as the Tang, this

backsword should be slightly in excess of 1.2 meters.) This weapon is stout and massive to chop through heavy

armour and continued to be in use in the Yuan, Ming and Qing dynasties.

◾ Use of ring pommels reintroduced.

◾ The importation of top quality, expensive and luxurious Japanese blades and Damascus wootz blades to China as

collectors' items, works of art.

◾ Near late Song and after, Mongols invade Japan twice, continental blades (i.e. Chinese, Korean and other makes)

are perceived by the Japanese as stouter, compared to their own native blades, prompting them to forge blades

with thicker backs and bigger points

Yuan Dynasty [1279–1368] (元)

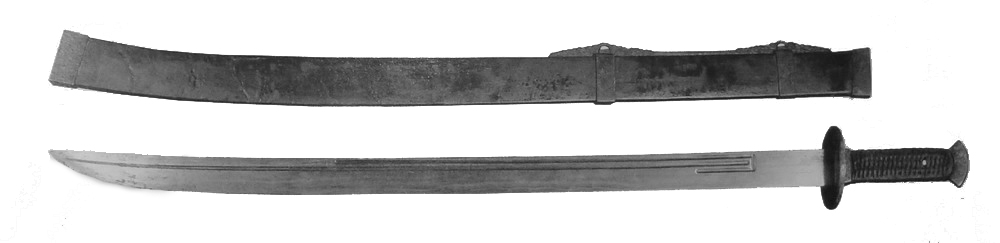

◾ The use of the Turko-Mongol saber is introduced into China, where it became the ancestor of the “liuye” and

goosequill Dao (liuyedao and yanmaodao) of the Ming and Qing dynasties, used by civilians and military men alike

◾ Use of rayskin to act as protective and decorative scabbard wrapping introduced

Ming Dynasty [1368–1644] (明)

◾ In early Ming, the process of making twist-core Damascus steel is transmitted to the Chinese sword-making world,

most likely from Indonesia and the Southern Philippines (thanks to Philip Tom's hypothesis)

◾ Use of clay in differential heat-treatment is not as common as in the Tang, smiths seem to prefer the non-clay

method

◾ Mass importation of Japanese swords (Wodao) to China in the early Ming

◾ Revival in the use of the ridged cross-section (a specific type known as shinogi-zukuri to the Japanese) in Chinese

dao, spurred by exposure to Japanese swords used by the pirates. General Qi Jiguang introduces the Changdao

for use in the Ming Imperial Army, a saber 2 meters long overall that is modelled after the nodachi used by the

Japanese pirates

◾ By the middle-to-late Ming, technical quality of Chinese dao made for northern border soldiers has been

compromised by inferior workmanship, resulting in these dao being of poor quality. General Qi Jiguang specifies

higher standards to bring quality up

Qing Dynasty [1644–1911] (清)

◾ New achievements and progress in sword-making (and various types of handicraft such as works in wood, glass,

metal, jade, porcelain etc.) achieved under Emperor Qianlong, a great improvement compared to the decline in

the Middle Ming

◾ Under him, a most comprehensive document titled Illustrated Regulations for the Ceremonial Paraphernalia of the

Qing Dynasty was compiled, and it records and standardizes various characteristics of the dao of the various

ranks of civil and military officials, amongst other things

◾ A comprehensive document titled "Weapons Workmanship Standards" is compiled (probably around the same time

as the above document) and stipulates the manufacture and quality control of Chinese dao, polearms etc.

◾ Occasional use of the ridged cross-section seen on Qing period dao

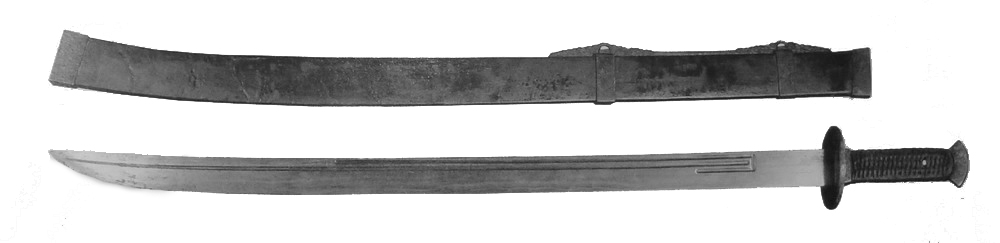

◾ Appearance of the oxtail dao (niuweidao) in the late Qing, where it was used exclusively by civilians and not by

the Qing military

Chinese Sword Today

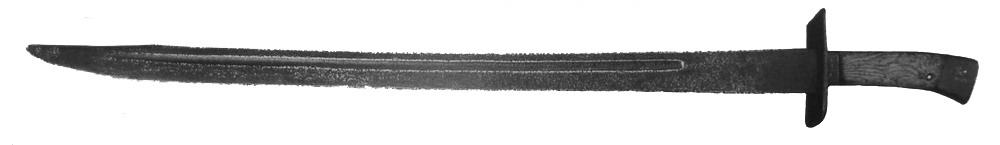

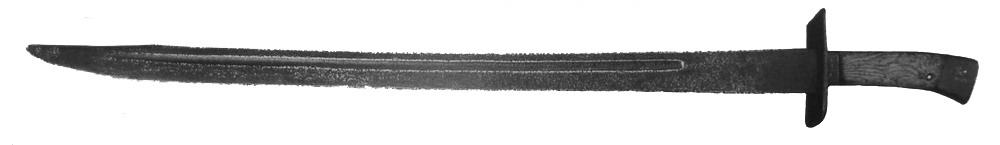

During the War of Resistance Against Japanese Aggression, the Broadsword team competed with the Japanese sword and wrote a special page in modern history; its blade was no different than a thick-backed chopper, the handle was slightly longer to facilitate the use of the hands, the handle was ringed, and the use of the force was fierce. It is extremely courageous and is called the “anti-war knife.” This is the last case of traditional Chinese tools used in war.

At the same time, a cold weapon used in conjunction with hot weapons was introduced to China, which is the sickle installed at the front end of the individual firearms. The file is usually composed of a knife body and a handle. It can be divided into a split type and a fold type. The former can be removed from the gun and loaded into the scabbard, and the latter is hinged to the gun side.

Now, Chinese swords are mainly used in collection and martial arts.

Swords have a long history in China. Stone swords were used in prehistoric times. Bronze swords have been traced back to the bronze daggers of the Shang period. Bronze long swords suddenly appeared during the mid-third century BC. Later swords were made of iron or steel. These metals were wrought, never cast. Swords commonly reached a length of 70–100 cm, although longer swords have been found. Chinese iron swords were used in Japan from the third to sixth century AD, but were replaced with Korean and native Japanese swords by the middle of the Heian era [794-1185].

Chinese group all swords into two types, Jian (劍) and Dao (刀). Jian are dual edged and Dao are single edged.

History of Chinese Sword

Late Spring and Autumn to Early Warring States [500–350 BC] (春秋战国时期)

◾ Unlaminated bronze Jian are well developed at this time. Appearance of the earliest laminated bronze jian where

they utilize bronze with higher tin content for the cutting edges and bronze with lower tin content for the spine. It

results in a sword with harder cutting edges and a more flexible spine to absorb shock

◾ Extensive use of copper sulphides as anti-corrosion coatings on the bronze Jian

◾ Earliest iron and steel jian also appear, made by the earliest and most basic forging and folding techniques

◾ World's earliest book on alloys, The Artificers' Record, is written, with an explicit statement on the percentage

composition of the metals used in the Chinese bronze Jian

Middle and Late Warring States [350–221 BC] (战国后期)

◾ Steel jian get longer to 1 meter or slightly more, with longer handles for two-handed use (though there are a few

Jian excavated that range from 1.2 to 1.4 meters)

◾ Bronze Jian also become longer to about 80 cm (earlier jian before have an average length of 60 cm and below)

Qin Dynasty [221–207 BC] (秦)

◾ Bronze Jian become even longer, reaching over 90 cm in length and the handle is extended to be long enough for

two-handed use

◾ Use of chromium oxide as an anti-corrosion protective coating on the bronze Jian. This process originates way

back from 700 BC. This invention was long lost for 2000 years before modern similar processes were developed

during our era in 1937 and the 1950s by Germans and Americans respectively

◾ The manufacture of steel jian that are 1 meter or longer is continued.

Early to Middle Han Dynasty [206 BC – 1 AD] (西汉)

◾ Longer steel Jian of length 1.2 meters or more are common

◾ Introduction of bronze Dao, followed by steel Dao. Steel Dao are as long as their steel double-edge counterparts

◾ Differential heat-treatment implemented on steel blades. This was to become a standardized process for the

construction of Chinese blades for the next 2000 years

◾ The prototype process of forging and folding sword blanks to improve the quality of the steel is further developed.

This particular process of forging and folding the sword blanks was to be perfected by the Middle Han (known as

the "refinings" process) to become a standardized process for later blades for almost 2000 years

◾ The introduction of ring pommels on bronze and steel Jian and Dao

◾ Earliest introduction of the tunkou (metal collar at the forte), made of bronze or copper

Middle to Late Han Dynasty [1–220 AD] (东汉/后汉)

◾ Bronze Jian and Dao, as well as steel jian are completely replaced by steel Dao

◾ Forge-welding/lamination (using higher carbon steel for the cutting edge and lower carbon steels for the core or

sandwich plates, depending on the design) introduced, a standardized process for later Chinese blades for almost

2000 years.

◾ Perfection of the forging and folding process resulting in blades being graded as thirty, fifty, and one hundred

"refinings". The higher the number, the better the blade's quality. This is the "refinings" process mentioned earlier.

It was also most likely transmitted to Korea.

◾ Earliest bronze and steel dao exported to Korea and Japan

◾ Use of white rayskin on the weapons' handle-grips introduced on Imperial Regulation blades

Early Three Kingdoms to Late Sui Dynasty [220–618] (三国早期至隋末)

◾ Continued use of the highly advanced "refinings" process

◾ Use of clay for differential heat-treatment introduced; when is unknown—it was invented sometime between 200

BC and 500 AD

◾ The development of the ridged cross-section (known later to the Japanese as kiriha-zukuri and shinogi-zukuri) in

the dao, probably sometime between 100 AD to 300 AD

◾ Introduction of the Sassanian/Persian style suspension mounts on Chinese Dao

◾ Probable introduction of Damascus wootz steel for use in Jian from India or the Middle East

Tang Dynasty [618–907] (唐)

◾ Swordmaking continues to progress in the Tang, maintaining the steady progress ever since the Han Dynasty

◾ Use of ring pommels discontinued in the Middle Tang

◾ Earliest use of disc-shaped guards to better protect the hand introduced in the Middle Tang

◾ Mass importation of quality Chinese blades to Japan in the Middle Tang

◾ Migration of Chinese and Korean swordsmiths to Japan where they transmitted their skills. Japanese smiths learn

from these smiths the processes of

◾ forge-welding/laminated construction

◾ ridged cross-sections (consisting of two variants known to the Japanese as kiriha-zukuri and shinogi-zukuri)

◾ differential heat-treatment using clay

◾ repeated forging and folding of sword blanks to enhance the quality of the steel ("refinings" process)

Song Dynasty [960–1279] (宋)

◾ Technical quality of Chinese weapons reaches a new high under Emperor Shenzong, a continuation from the Tang.

Multiple weapons quality assessment bureaus are set up. A manual on weapons manufacture and quality control,

Weapons' Laws and Methods is compiled and distributed to the relevant government bodies

◾ Under Emperor Shenzong, the horse-chopping backsword, or "zhanmadao", a heavy two-handed sword used by

anti-cavalry infantry is introduced in 1072 AD. (If Song dimensions are exactly the same as the Tang, this

backsword should be slightly in excess of 1.2 meters.) This weapon is stout and massive to chop through heavy

armour and continued to be in use in the Yuan, Ming and Qing dynasties.

◾ Use of ring pommels reintroduced.

◾ The importation of top quality, expensive and luxurious Japanese blades and Damascus wootz blades to China as

collectors' items, works of art.

◾ Near late Song and after, Mongols invade Japan twice, continental blades (i.e. Chinese, Korean and other makes)

are perceived by the Japanese as stouter, compared to their own native blades, prompting them to forge blades

with thicker backs and bigger points

Yuan Dynasty [1279–1368] (元)

◾ The use of the Turko-Mongol saber is introduced into China, where it became the ancestor of the “liuye” and

goosequill Dao (liuyedao and yanmaodao) of the Ming and Qing dynasties, used by civilians and military men alike

◾ Use of rayskin to act as protective and decorative scabbard wrapping introduced

Ming Dynasty [1368–1644] (明)

◾ In early Ming, the process of making twist-core Damascus steel is transmitted to the Chinese sword-making world,

most likely from Indonesia and the Southern Philippines (thanks to Philip Tom's hypothesis)

◾ Use of clay in differential heat-treatment is not as common as in the Tang, smiths seem to prefer the non-clay

method

◾ Mass importation of Japanese swords (Wodao) to China in the early Ming

◾ Revival in the use of the ridged cross-section (a specific type known as shinogi-zukuri to the Japanese) in Chinese

dao, spurred by exposure to Japanese swords used by the pirates. General Qi Jiguang introduces the Changdao

for use in the Ming Imperial Army, a saber 2 meters long overall that is modelled after the nodachi used by the

Japanese pirates

◾ By the middle-to-late Ming, technical quality of Chinese dao made for northern border soldiers has been

compromised by inferior workmanship, resulting in these dao being of poor quality. General Qi Jiguang specifies

higher standards to bring quality up

Qing Dynasty [1644–1911] (清)

◾ New achievements and progress in sword-making (and various types of handicraft such as works in wood, glass,

metal, jade, porcelain etc.) achieved under Emperor Qianlong, a great improvement compared to the decline in

the Middle Ming

◾ Under him, a most comprehensive document titled Illustrated Regulations for the Ceremonial Paraphernalia of the

Qing Dynasty was compiled, and it records and standardizes various characteristics of the dao of the various

ranks of civil and military officials, amongst other things

◾ A comprehensive document titled "Weapons Workmanship Standards" is compiled (probably around the same time

as the above document) and stipulates the manufacture and quality control of Chinese dao, polearms etc.

◾ Occasional use of the ridged cross-section seen on Qing period dao

◾ Appearance of the oxtail dao (niuweidao) in the late Qing, where it was used exclusively by civilians and not by

the Qing military

Chinese Sword Today

During the War of Resistance Against Japanese Aggression, the Broadsword team competed with the Japanese sword and wrote a special page in modern history; its blade was no different than a thick-backed chopper, the handle was slightly longer to facilitate the use of the hands, the handle was ringed, and the use of the force was fierce. It is extremely courageous and is called the “anti-war knife.” This is the last case of traditional Chinese tools used in war.

At the same time, a cold weapon used in conjunction with hot weapons was introduced to China, which is the sickle installed at the front end of the individual firearms. The file is usually composed of a knife body and a handle. It can be divided into a split type and a fold type. The former can be removed from the gun and loaded into the scabbard, and the latter is hinged to the gun side.

Now, Chinese swords are mainly used in collection and martial arts.

Recently Reviews

Read MoreLeave a Reply

Your email address will not be published.Required fields are marked. *