By lyuesword | 15 January 2021 | 0 Comments

Know about Blade Grinds

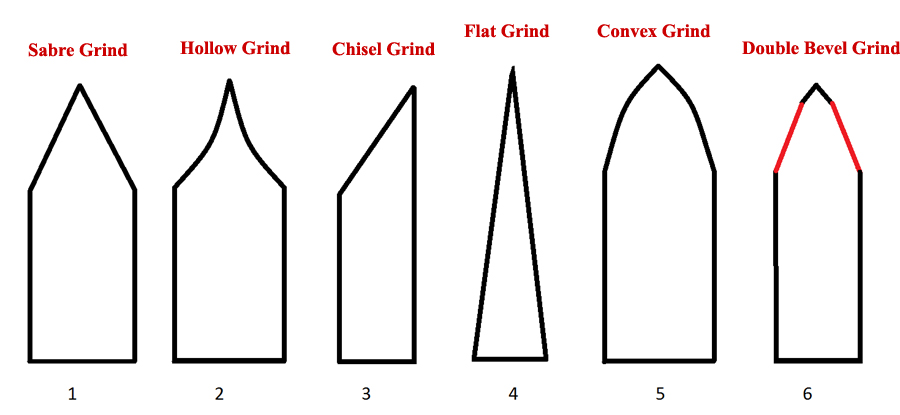

Building a sword is a methodical and time-consuming process. In feudal Japan, swordsmiths often spent months creating a katana. Even polishing the sword would take several weeks. However, one of the most important steps in this process was grinding the blade, which ultimately created the sharp tip. Here are the six most common blade grinds used to make swords and other bladed weapons.

#1) Sabre Grind

Finally, the sabre grind is characterized by a moderate point in which the bevel begins in the middle of the blade rather than the spine. Also known as the V grind, it offers a high level of strength and durability, making it a popular choice for use in the construction of military knives and swords. When the sabre grind only has a single bevel, it's called a Scandinavian grind.

#2) Hollow Grind

Used to create exceptionally sharp swords and knives, the hollow grind featured a beveled cutting edge that's characterized by a razor-sharp tip. While sharp, the hollow grind makes the blade susceptible to damage, as moderate stress may cause the beveled edge to chip, break or otherwise degrade.

#3) Chisel Grind

The chisel grind features a single side that's chiseled at a 20- to 30-degree angle. This means only a single edge is angled, reducing its effectiveness for military-grade swords and bladed weapons. However, the chisel grind is still used in many Japanese culinary knives due to its simplicity and aesthetics.

#4) Flat Grind

A popular alternative to the hollow grind is the flat grind, which is characterized by a blade that tapers equally from the spine on the edges. To create a flat grind, the swordsmith or bladesmith must remove a significant amount of the blade. This makes it somewhat more difficult and laborious than other grind types. However, the flat grind offers a balanced level of strength and protection from damage.

#5) Convex Grind

The convex grind featured a curved taper instead of the traditional straight lines. This helps to maintain the metal behind the edge to create a superior level of strength and sharpness. The downside to the convex grind, however, is that it requires the use of thicker stock materials than other grind types.

#6) Double Bevel Grind

Also known as a compound bevel, the double bevel grind is a more complex grind that's characterized by a somewhat broad edge that sacrifices sharpness for strength and durability.

Want a unique sword? Feel free to contact us:

Email: lyuesword@hotmail.com

Website: www.lyuesword.com

Custom Sword Page: www.lyuesword.com/Custom-Sword/customization-options/Create-Your-Own-Swords

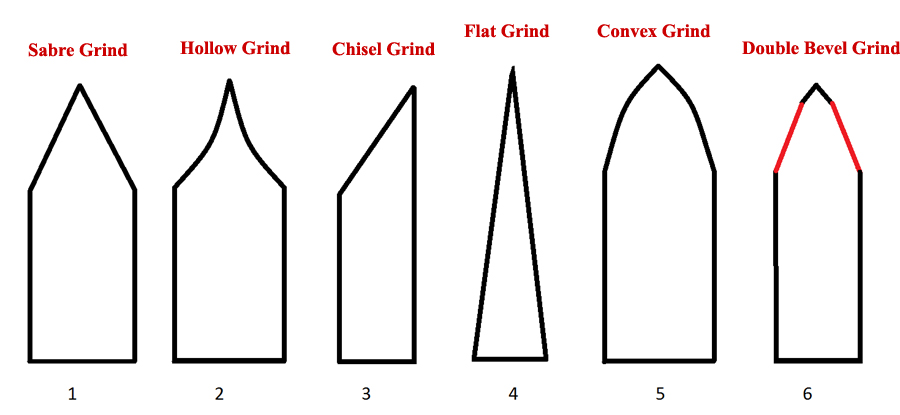

#1) Sabre Grind

Finally, the sabre grind is characterized by a moderate point in which the bevel begins in the middle of the blade rather than the spine. Also known as the V grind, it offers a high level of strength and durability, making it a popular choice for use in the construction of military knives and swords. When the sabre grind only has a single bevel, it's called a Scandinavian grind.

#2) Hollow Grind

Used to create exceptionally sharp swords and knives, the hollow grind featured a beveled cutting edge that's characterized by a razor-sharp tip. While sharp, the hollow grind makes the blade susceptible to damage, as moderate stress may cause the beveled edge to chip, break or otherwise degrade.

#3) Chisel Grind

The chisel grind features a single side that's chiseled at a 20- to 30-degree angle. This means only a single edge is angled, reducing its effectiveness for military-grade swords and bladed weapons. However, the chisel grind is still used in many Japanese culinary knives due to its simplicity and aesthetics.

#4) Flat Grind

A popular alternative to the hollow grind is the flat grind, which is characterized by a blade that tapers equally from the spine on the edges. To create a flat grind, the swordsmith or bladesmith must remove a significant amount of the blade. This makes it somewhat more difficult and laborious than other grind types. However, the flat grind offers a balanced level of strength and protection from damage.

#5) Convex Grind

The convex grind featured a curved taper instead of the traditional straight lines. This helps to maintain the metal behind the edge to create a superior level of strength and sharpness. The downside to the convex grind, however, is that it requires the use of thicker stock materials than other grind types.

#6) Double Bevel Grind

Also known as a compound bevel, the double bevel grind is a more complex grind that's characterized by a somewhat broad edge that sacrifices sharpness for strength and durability.

Want a unique sword? Feel free to contact us:

Email: lyuesword@hotmail.com

Website: www.lyuesword.com

Custom Sword Page: www.lyuesword.com/Custom-Sword/customization-options/Create-Your-Own-Swords

Leave a Reply

Your email address will not be published.Required fields are marked. *